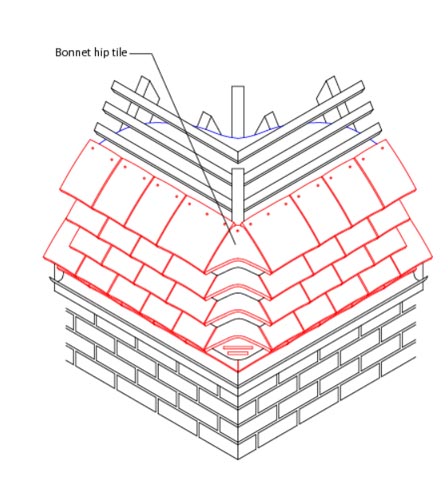

Hip details on a plain clay tiled roof

Hip with bonnet hip tiles

Lay courses of underlay over hip with overlaps of not less than 150mm. Bed bonnet hip tiles in mortar, coursing in with general tiling and fix to hip rafter with nails recommended by tile manufacturer. To avoid an excessive depth of mortar between bonnet hip tiles asupplementary hip batten should be used if necessary.

Strike mortar back neatly about 13mm from edge of bonnet hip tile leaving the edges clean. Fill end of first hip tile with mortar and tile slips finished flush.

Cut adjacent tiles and tile-and-a-half tiles to fit neatly.

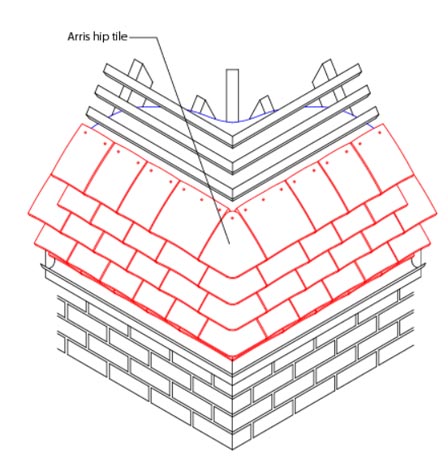

Hip with arris hip tiles

Hip with arris hip tiles

Lay courses of underlay over hip with overlaps of not less than 150mm.

Spot bed arris hip tiles in mortar, coursing in with general tiling and fix to hip rafter with nails recommended by tile manufacturer.

Cut adjacent tiles and tile-and-a-half tiles to fit neatly.

Note: Arris hip tiles are manufactured to suit specific rafter pitches, therefore the correct rof pitch must be stated when ordering

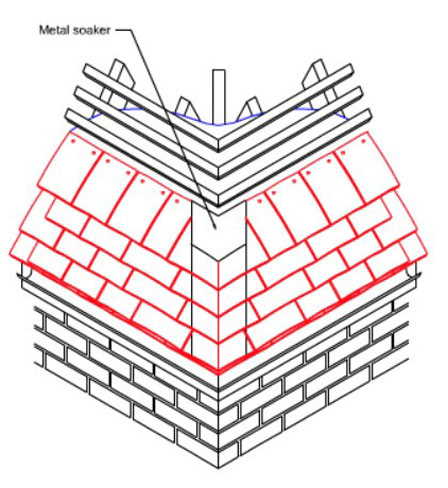

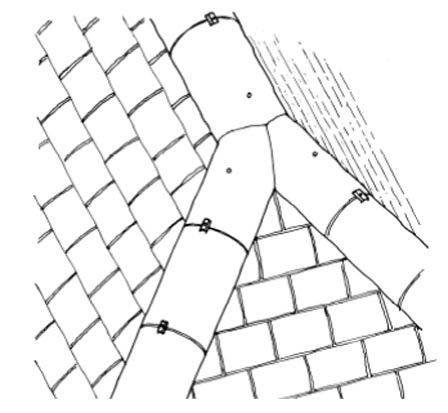

Mitred hip with metal soakers

Mitred hip with metal soakers

Lay courses of underlay over hip with overlaps of not less than 150mm. Cut tile-and-a-half tiles and fix to form a straight, weathertight, close mitred junction.

Interleave mitred tiles with metal soakers, extending a minimum 100mm to each side of hip. Fix soakers by turning down over heads of mitred tiles.

Note: Extreme care is needed to achieve a neat finish at the hip. Where possible it advisable to use either bonnet hip tiles or specify specially made arris hip tiles to suit the particular roof pitch instead.

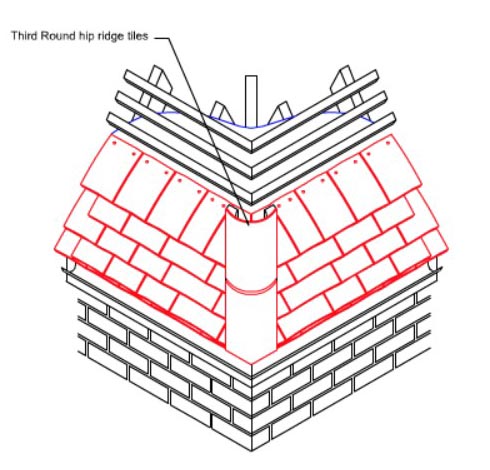

Bedded hip with hip ridge tiles

lay courses of underlay over hip with overlaps of not less than 150mm. Cut and fix tiles closely at junction.

Fix hip iron to hip rafter or hip batten with galvanised steel screws.

Lay hip tiles by continuously bedding at edges and solidly bedding with tile slips inserted into mortar at joints between hip tiles.

European Standard BS EN 5534 requires all ridge tiles, including ridge tiles used down the hips, to be mechanically fixed. We can supply cleats and screws to do this. The end ridge tiles in a row (both top and bottom) should not be secured with a cleat, but instead should have a hole drilled in and then be secured by a screw through a rubber washer.

Shape first hip tile neatly to align with corner of eaves and fill end with mortar and slips of tile finished flush.

Note: The use of ridge hip tiles should be avoided where possible in favour of the use of bonnet or arris hip tiles.

Hip with ridge roll ventilation system

European Standard BS EN 5534 requires all ridge tiles, including ridge tiles used down the hips, to be mechanically fixed. We can supply cleats and screws to do this. The end ridge tiles in a row (both top and bottom) should not be secured with a cleat, but instead should have a hole drilled in and then be secured by a screw through a rubber washer.

It is important that the ridge hip tiles are NOT mortared in if the Tileline Ridgeroll ventilation system is being used. Instead, the ridge hips are secured with special clips (supplied as part of the system) and air is left to circulate between the ridge tiles, thus providing the ventilation.

download instructions on fitting the ridgeroll ventilation system

-A.jpg)