1805 The year of the Battle of Trafalgar and a Brick and Tile Works is established on present site. Subsequently the tiles were named after Nelson's iconic battleship, HMS Dreadnought.

1805 The year of the Battle of Trafalgar and a Brick and Tile Works is established on present site. Subsequently the tiles were named after Nelson's iconic battleship, HMS Dreadnought. 1902 R.S Davenhill a mining engineer joins Messrs Hinton and Perry to design and establish an entirely new modern plant.

1902 R.S Davenhill a mining engineer joins Messrs Hinton and Perry to design and establish an entirely new modern plant. 1914-18 Progress halted by the Great War. 5 employees killed 9 wounded 5 POW

1914-18 Progress halted by the Great War. 5 employees killed 9 wounded 5 POW 1919 R.E Davenhill(Peter) returns from war service and with Edgar Perry starts to reestablish the business which grows continuously until 1939.

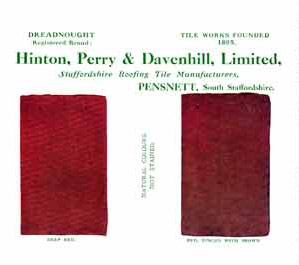

1919 R.E Davenhill(Peter) returns from war service and with Edgar Perry starts to reestablish the business which grows continuously until 1939. 1912 Dreadnought’s first brochure was produced.

1912 Dreadnought’s first brochure was produced. 1930 The Ketley Quarry and surrounding land purchased to ensure future marl supply.

1930 The Ketley Quarry and surrounding land purchased to ensure future marl supply.1935 Two producer gas fired continuous 18 chamber kilns constructed. These proved to be the most fuel efficient kilns in the clay roof tile industry for the next 35 years.

1939-45 Production virtually halted by WW2

1964 Ketley Brick a local Staffs Blue and Red brick works is purchased and their production moved to the Dreadnought works. Much of the manual labour carried out by women

1964 Ketley Brick a local Staffs Blue and Red brick works is purchased and their production moved to the Dreadnought works. Much of the manual labour carried out by women Traditional bat roll methods were used to form the tiles

Traditional bat roll methods were used to form the tiles 1967 A major fire and another in 1971 necessitates a rapid reconstruction of the plant and buildings.

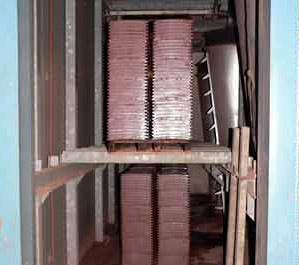

1967 A major fire and another in 1971 necessitates a rapid reconstruction of the plant and buildings. 1972 New natural gas fired shuttle kilns constructed. The entire works now used gas for both drying and firing and all coal consumption ceased. 1986 “Skate” tunnel kiln installed, the first kiln in the UK to fire tiles on edge one tile high. This advance importantly retained Dreadnought's method of firing in natural colour.

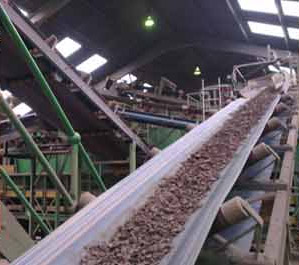

1972 New natural gas fired shuttle kilns constructed. The entire works now used gas for both drying and firing and all coal consumption ceased. 1986 “Skate” tunnel kiln installed, the first kiln in the UK to fire tiles on edge one tile high. This advance importantly retained Dreadnought's method of firing in natural colour. 1998 to present day. Continued Intensive investment program to increase energy and production efficiency Investment in Clay preparation - wet pan and high speed rolls.

1998 to present day. Continued Intensive investment program to increase energy and production efficiency Investment in Clay preparation - wet pan and high speed rolls. 1998 Investment in tile extrusion and a new bespoke tile line

1998 Investment in tile extrusion and a new bespoke tile line Investment in new energy efficient dryers

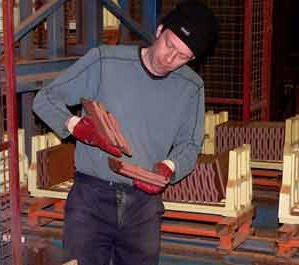

Investment in new energy efficient dryers Despite technological changes the company’s conviction about natural colour and product quality are still the same and product is still sorted by hand.

Despite technological changes the company’s conviction about natural colour and product quality are still the same and product is still sorted by hand. Dreadnought still produce bespoke fittings and components by hand.

Dreadnought still produce bespoke fittings and components by hand. 2005 Launch of Mixed Colour Blends to commemorate 200 years of history.

2005 Launch of Mixed Colour Blends to commemorate 200 years of history. 2010 Dreadnought launch Classic handmade tiles, replicating their old handmades produced between 1805 and 1984.

2010 Dreadnought launch Classic handmade tiles, replicating their old handmades produced between 1805 and 1984. 2015 Dreadnought extend their range with new Rustic handcrafted tiles bridging the gap between handmade and machinemades

2015 Dreadnought extend their range with new Rustic handcrafted tiles bridging the gap between handmade and machinemades

-A.jpg)