The fitting of Ridges on a plain clay tile roof

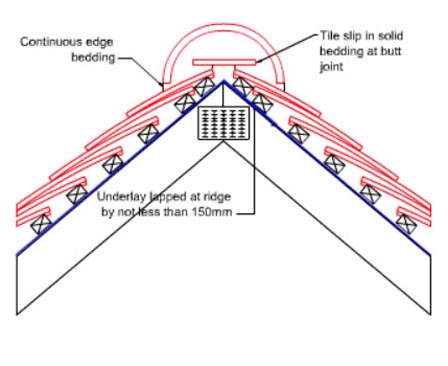

Bedded Ridge

Bedded Ridge

Lay top course of underlay from one side of ridge over apex to overlap top course at other side by not less than 150mm.

Fix finishing courses of tops tiles. Lay ridge tiles by continuously bedding at edges and solidly bedding with tile slips inserted into mortar at joints between ridges.

The New British Standard BS 5534 requires all ridge tiles to be mechanically fixed. Fix each tile with a cleat or clip and a screw before the mortar goes off

Fill ends of ridges at gables with mortar and slips of tiles finished flush.

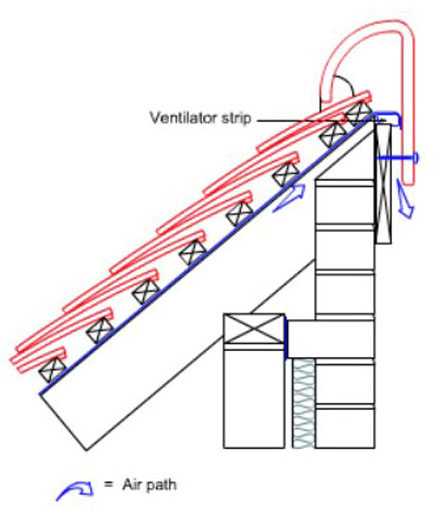

Bedded Monopitch ridge

Carry top course of underlay over apex by not less than 150mm. Fix finishing course of tops tiles. Lay ridge tiles by continuously bedding at sloping edge and solidly bedding with tile slips inserted into mortar at joints between ridges.

Fix vertical face of ridge tiles to ridge fixing batten with screws or nails as recommended by manufacturer.

Fill ends of ridges at gables with mortar and slips of tiles finished flush.

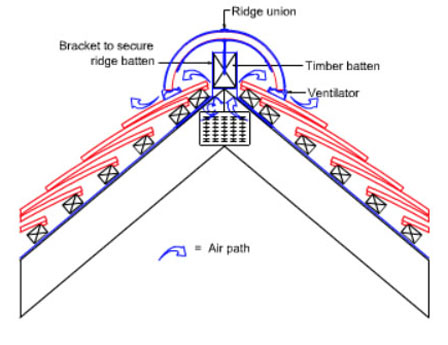

Dry Fix Ridge

Ensure dry ridge system is compatible with particular tiles and ridges. Check with manufacturer for advice. Terminate underlay 30mm from apex, or as recommended by manufacturer. If required fix appropriate supplementary ridge batten. Fix finishing courses of tops tiles maintaining specified headlap and with clearance to ridge batten. Fit dry ridge system and ridge tiles in accordance with Manufacturers Recommendations.

Use stop end or block end ridges at gables.

Click here for more info on fitting of Dreadnought ridge tiles

Ridge with tileline ridgeroll ventilation

This system is suitable for all Dreadnought ridge tiles except capped angle ridges and is quick and easy to install. It is now mandatory, with the introduction of the new British Standard BS 5534, to mechanically fix all ridge tiles whether they are used on the ridge or or the hip line. The ridgeroll product comes in 6m boxes and consists of a corrugated grey coated aluminium roll which is laid out centrally on the ridge and temporarily fixed with double-sided adhesive tape. The ridge tiles are then laid over the top securing the roll in place leaving 10mm joints between each ridge. A cleat is then placed over the joint between the ridge tiles and screwed down into the ridge board.

For ornamental ridges, a butterfly clip is used to attach on to the ridge tiles and provide a fixing that can be screwed into the roof timber

-A.jpg)